Exploring the World of Plastic Mold Manufacturers in China

In the ever-evolving realm of manufacturing, plastic mold manufacturers in China have carved a significant niche for themselves on the global stage. The unparalleled expertise, commitment to quality, and cost-effectiveness offered by these manufacturers make them a go-to choice for businesses worldwide seeking efficient injection mold solutions.

The Rise of Plastic Mold Manufacturing in China

Over the past few decades, China has emerged as a dominant player in the field of plastic mold manufacturing. Fueled by rapid industrialization, advancements in technology, and a skilled workforce, plastic mold manufacturers in China have become synonymous with high-quality production and innovative methodologies.

Why Choose China for Plastic Molding Solutions?

Several factors contribute to the decision of international businesses to partner with plastic mold manufacturers in China. Some of these factors include:

- Cost Efficiency: China offers competitive pricing without compromising on quality. The economics of scale allow manufacturers to reduce costs significantly.

- Advanced Technology: Manufacturers in China invest heavily in the latest technology and machinery, ensuring that they stay at the forefront of the industry.

- Skilled Workforce: With a vast pool of trained professionals, China boasts a labor force that is well-versed in the nuances of plastic molding techniques.

- Quick Turnaround Times: The streamlined processes in Chinese factories facilitate quicker production and delivery of molds, meeting urgent project deadlines.

- Diverse Specialization: From automotive parts to consumer goods, Chinese mold manufacturers cater to a wide range of industries, offering specialized services tailored to specific needs.

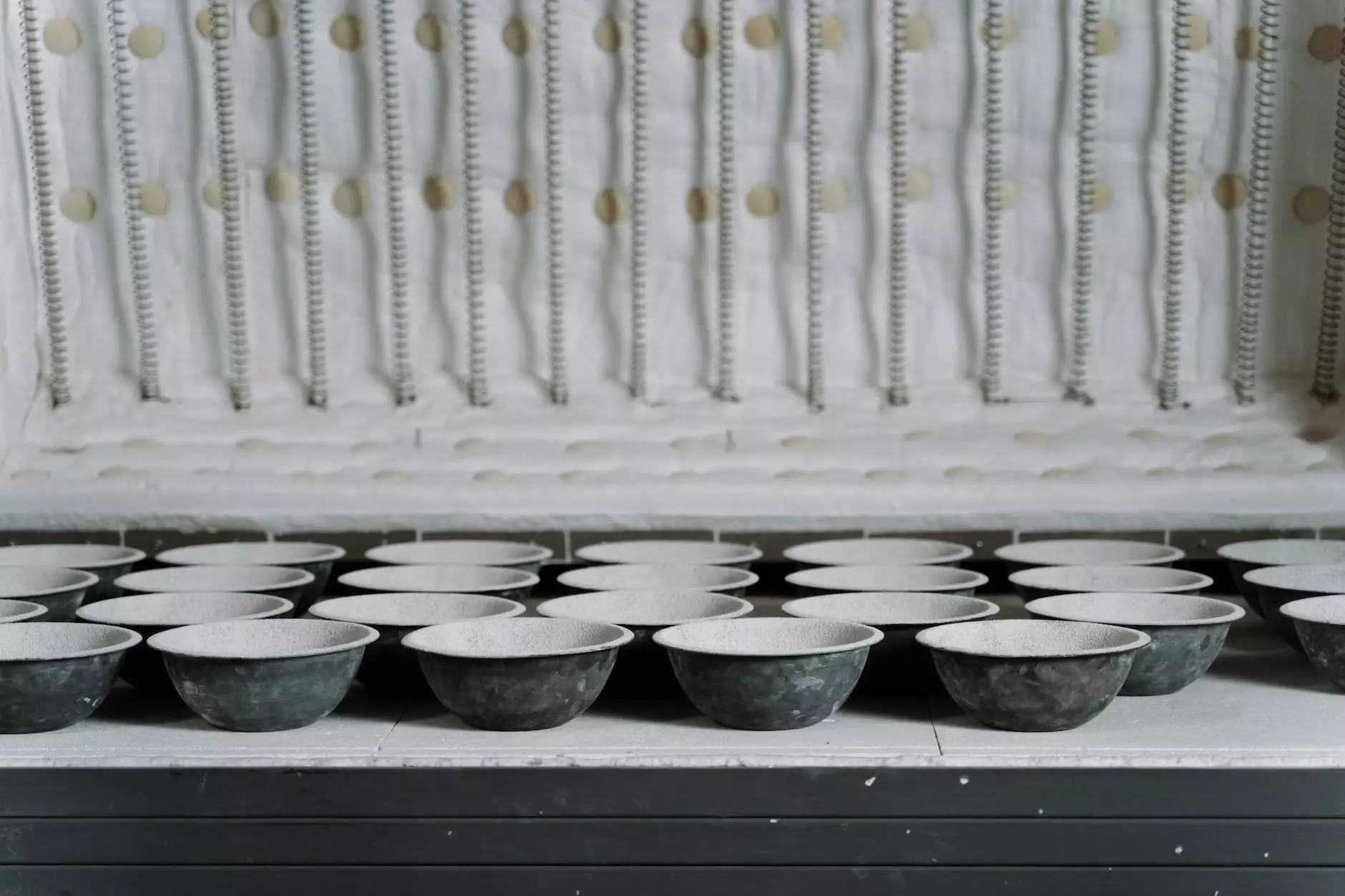

Understanding the Plastic Injection Molding Process

To fully appreciate the capabilities of plastic mold manufacturers in China, it's essential to understand the plastic injection molding process itself. This manufacturing method involves:

- Material Preparation: Plastic pellets are heated until they melt, forming a viscous liquid.

- Injection: The molten plastic is injected into a mold cavity at high pressure.

- Cooling: Once the mold is filled, the plastic cools and solidifies into the desired shape.

- Mold Opening: The mold is opened, and the finished product is ejected.

- Finishing: Additional processes such as trimming and surface treatment may be applied to enhance the final product.

This efficient method allows for the mass production of intricate parts with precision and consistency, a hallmark of the industry led by plastic mold manufacturers in China.

Key Categories of Mold Manufacturers

Within the sphere of plastic mold manufacturers in China, there are two prominent categories:

1. Plastic Mold Makers

These are specialized manufacturers that focus on designing and producing molds. They work closely with clients to create custom solutions tailored to specific product requirements. The expertise of plastic mold makers lies in:

- Design Innovation: Utilizing advanced CAD/CAM software to create precise and efficient mold designs.

- Material Selection: Ensuring the right type of plastic is chosen based on the application, mechanical properties, and durability.

- Prototype Development: Creating prototypes to test the design and functionality before full-scale production.

2. Plastic Injection Mould Manufacturers

These manufacturers specialize in the production of injection molds specifically. They have the capability to produce complex molds that facilitate the injection molding process. Their strengths include:

- High-Volume Production: Capable of producing large quantities of parts, making them ideal for mass production runs.

- Complex Mold Designs: Expertise in creating molds with intricate geometries and features.

- Efficient Quality Control: Implementing stringent quality checks at every stage of the molding process to ensure top-quality outcomes.

Choosing the Right Manufacturer

With a plethora of plastic mold manufacturers in China available, selecting the right one is crucial for your business success. Here are some essential criteria to consider:

1. Experience and Reputation

Evaluate the manufacturer's experience in the field. Look for reviews, testimonials, and case studies that showcase their work quality and reliability. An established manufacturer with a solid reputation will likely deliver better results.

2. Technology and Equipment

Inspect the technology and machinery utilized by the manufacturer. State-of-the-art equipment not only enhances production efficiency but also contributes to the accuracy and quality of the molds.

3. Customization Capabilities

Your project may require unique specifications. Ensure the manufacturer has the capability to offer customized solutions tailored to your precise needs.

4. Communication and Support

Effective communication is vital for successful collaboration. The manufacturer must provide responsive support, keeping you informed throughout the production process.

5. Compliance and Certifications

Check whether the manufacturer complies with international quality standards and possesses necessary certifications. This ensures that the products meet safety and quality requirements.

The Future of Plastic Mold Manufacturing in China

As global demand for innovative and sustainable products continues to rise, the future of plastic mold manufacturers in China looks exceedingly promising. Several trends are shaping the industry:

- Embracing Sustainability: Manufacturers are increasingly adopting eco-friendly practices by utilizing biodegradable materials and minimizing waste during production.

- Digital Transformation: The incorporation of Industry 4.0 technologies, such as IoT and automation, is enhancing operational efficiency and product quality.

- Focus on R&D: An increased emphasis on research and development is leading to the innovation of new materials and molding techniques, ensuring manufacturers remain competitive.

- Global Partnerships: As international businesses seek reliable suppliers, many Chinese manufacturers are forming strategic partnerships, expanding their global footprint.

Conclusion: Partner with Hanking Mould for Quality Solutions

In conclusion, the landscape governed by plastic mold manufacturers in China is vast and promising. With expertise, technology, and a commitment to quality, they can transform your ideas into reality, enhancing your product offerings and business growth.

At Hanking Mould, we are proud to be at the forefront of this industry, providing unparalleled services as a plastic injection mould manufacturer. Our dedication to innovation, quality, and customer satisfaction makes us an ideal partner for businesses seeking reliable and efficient plastic mold solutions.

If you're looking to take your production capabilities to the next level, contact us today to explore how we can assist you!